Introduction

In the world where sustainability is becoming not just a trend but a necessity, the manufacturing sector, particularly those involved in producing zinc alloy bottle caps, is not left behind. It’s crucial to understand the impact of our choices, especially when it involves materials that we use daily. As a customized zinc alloy bottle cap manufacturer, we are constantly exploring ways to blend functionality with environmental responsibility. This article delves into the sustainability of zinc alloy, a popular material in the bottle cap industry, and why it’s gaining traction among eco-conscious producers and consumers alike.

What is Zinc Alloy?

Zinc alloy, renowned for its robustness and versatility, is a preferred material in various industries, especially in the realm of bottle cap production. As a composite of zinc mixed with other elements like aluminum, copper, and magnesium, it offers an exemplary balance of strength and malleability. This unique combination makes it ideal for creating customized zinc alloy bottle caps, which need to be durable yet adaptable to different designs and purposes. The inherent properties of zinc alloy, such as corrosion resistance and low melting point, also contribute to its efficiency in manufacturing, making it a go-to choice for zinc alloy cap producers looking to merge quality with practicality.

The Sustainability Angle

When it comes to sustainability, zinc alloy stands out in the materials world. Its recyclability is a key factor that makes it an eco-friendly choice for bottle cap manufacturing. Unlike some materials that degrade in quality when recycled, zinc alloy maintains its properties, allowing it to be reused repeatedly without losing integrity. This recyclability significantly reduces waste and conserves natural resources, a crucial aspect for sustainable zinc alloy bottle cap manufacturers.

Furthermore, zinc alloy’s low melting point contributes to a lower carbon footprint during production. It requires less energy to melt and mold compared to other metals, making it a more energy-efficient option. This efficiency is particularly beneficial for custom zinc alloy cap producers, as it allows for the creation of high-quality products with minimal environmental impact. Additionally, the durability of zinc alloy means products last longer, reducing the need for frequent replacements and further contributing to sustainability.

Customization and Environment

The intersection of customization and environmental sustainability is where zinc alloy truly shines. For customized zinc alloy bottle cap manufacturers, the ability to tailor designs without compromising on eco-friendliness is a significant advantage. The versatility of zinc alloy allows for a wide range of custom designs, catering to various client needs while maintaining an environmentally responsible manufacturing process.

Custom zinc alloy caps can be produced with minimal waste, as the precision in manufacturing ensures efficient use of materials. This efficiency is crucial for zinc alloy cap producers aiming to reduce their environmental footprint. Moreover, the long-lasting nature of zinc alloy means fewer replacements over time, which translates to less material usage and waste. For businesses and consumers who prioritize both uniqueness and sustainability, custom zinc alloy bottle caps offer an ideal solution that aligns with their values.

Common Questions Answered

Q1: How durable are zinc alloy bottle caps?

A: Zinc alloy caps are known for their exceptional durability. They resist corrosion and can withstand various environmental factors, making them a long-lasting choice for bottle caps.

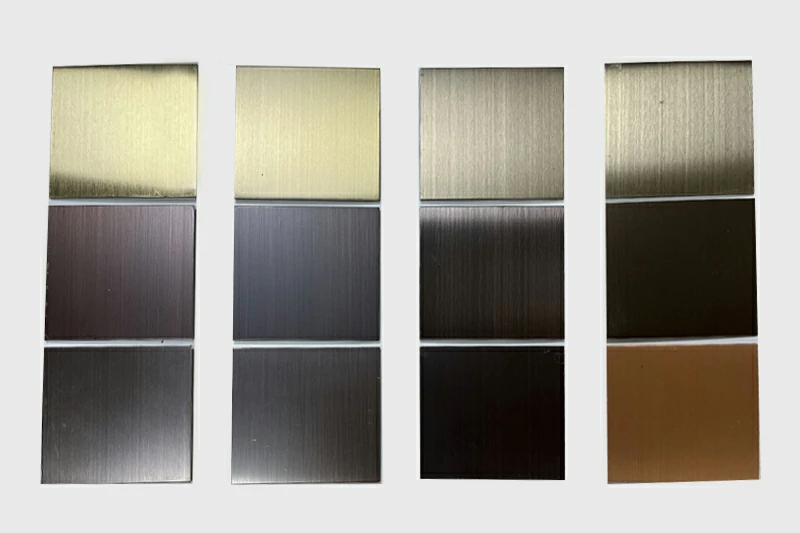

Q2: What customization options are available with zinc alloy caps?

A: As a custom zinc alloy bottle cap manufacturer, the possibilities are vast. You can choose from different shapes, sizes, and finishes. Engravings and embossing are also popular choices for adding a unique touch.

Q3: What’s the environmental impact of using zinc alloy for bottle caps?

A: Zinc alloy is highly recyclable, which lessens its environmental impact. Its production requires less energy, and its durability means less frequent replacements, making it a sustainable choice in the long run.

Q4: Are zinc alloy caps safe for food and beverage use?

A: Absolutely. Zinc alloy is safe for use in food and beverage applications. It doesn’t react with the contents and maintains the integrity of the product it seals.

Q5: Can zinc alloy caps be customized for any bottle type?

A: Yes, one of the benefits of working with a zinc alloy bottle cap producer is the flexibility in design. Whether it’s for wine, spirits, or non-alcoholic beverages, zinc alloy caps can be tailored to fit various bottle types.

Why Choose Zinc Alloy Caps for Your Project

Opting for zinc alloy bottle caps is a smart move for businesses looking to balance quality, aesthetics, and environmental responsibility. These caps offer a premium feel, adding a touch of class to any product. Their durability ensures the longevity of your packaging, while their recyclability aligns with eco-friendly business practices.

For those seeking customization, zinc alloy cap manufacturers provide extensive options to match any branding or design requirement. This flexibility, combined with the material’s sustainable attributes, makes zinc alloy caps an excellent choice for companies conscious of their environmental impact and committed to delivering quality products.

Conclusion

In an era where sustainability is not just a buzzword but a business imperative, zinc alloy bottle caps stand out as an exemplary choice for both their environmental and aesthetic benefits. As a customized zinc alloy bottle cap manufacturer, embracing this material means committing to quality, creativity, and care for the planet. Whether for a boutique brand or a large-scale production, zinc alloy caps offer a versatile, durable, and eco-friendly solution, ticking all the boxes for modern packaging needs.