Welcome to the fascinating world of custom zinc alloy bottle caps! In this journey, we’re diving into how a simple sketch evolves into a stunning, tailor-made bottle cap. Perfect for brands looking for that unique touch, custom bottle caps can transform the packaging into a statement piece. Let’s explore how these bespoke beauties come to life courtesy of skilled zinc alloy bottle cap manufacturers.

Understanding Zinc Alloy

Zinc alloy, a go-to material for top-tier custom bottle cap manufacturers, stands out for its superb qualities. This alloy, typically a blend of zinc with elements like copper, aluminum, and magnesium, offers incredible durability and versatility in design. Ideal for crafting detailed and intricate designs, zinc alloy ensures that each custom bottle cap isn’t just strong but also aesthetically pleasing. Its resistance to corrosion and ability to hold up against wear and tear makes it a prime choice for bottle cap fabrication.

Step 1: The Design Phase

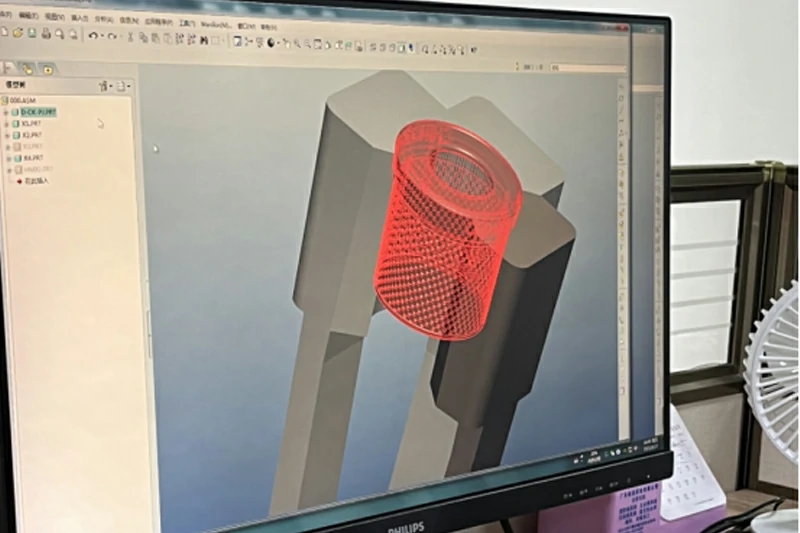

Creating a custom zinc alloy bottle cap starts with an idea – a vision in the client’s mind. This is where the magic begins. Skilled designers at a zinc alloy bottle cap manufacturer collaborate closely with clients and bring these ideas to life. They craft initial designs using advanced software, ensuring every detail aligns with the client’s brand identity and vision.

This phase is all about creativity and precision. It’s not just about crafting a cap; it’s about encapsulating a brand’s essence. This step lays the foundation for a hat that truly represents the brand, whether it’s intricate logos, unique textures, or specific patterns. The design is then refined through client feedback, ensuring the final product is nothing short of perfect.

Step 2: Prototyping and Approval

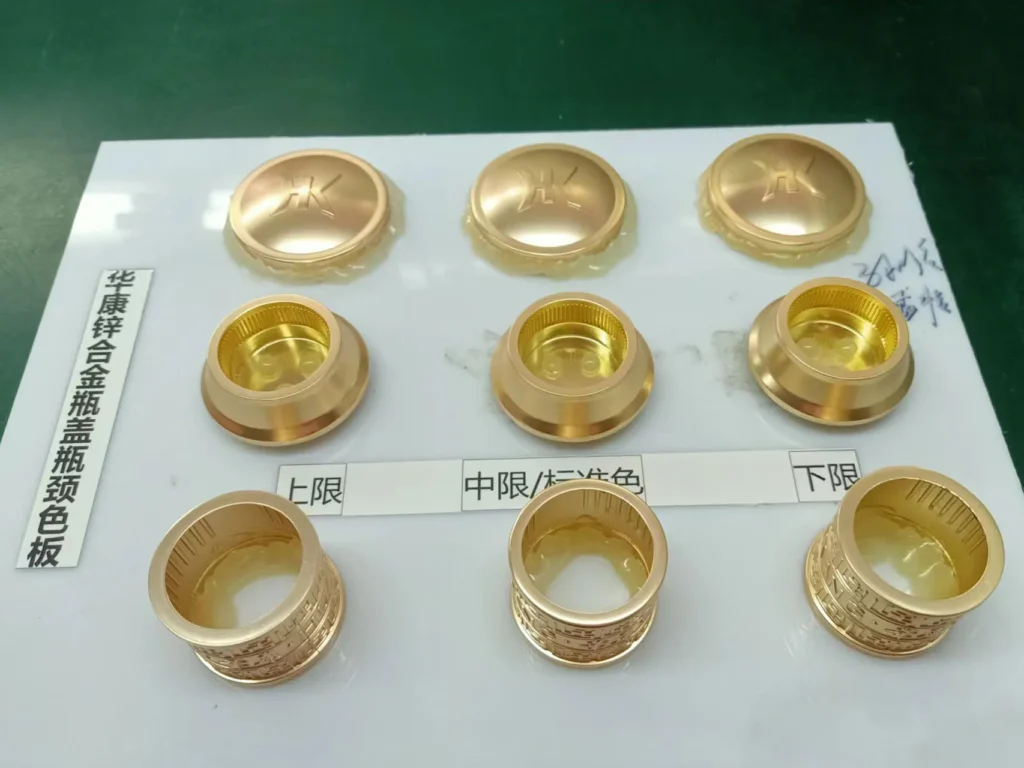

Once the design is locked in, the next step for a zinc alloy bottle cap manufacturer is to bring that design into the physical world. A prototype is created as a tangible preview of the final product. This is where clients get a natural feel for their custom bottle cap, examining everything from the weight to the texture.

The prototyping phase is crucial for both the manufacturer and the client. It’s the stage where ideas are tested and adjustments are made. Feedback from the client is critical here. They could tweak the design, alter the dimensions, or change the finish. It’s all about getting that cap to a point where the client says, “Yes, this is exactly what I envisioned!”

Once the client approves, the prototype serves as the blueprint for mass production. It’s the green light for the manufacturer to craft the final product.

Step 3: The Manufacturing Process

Transitioning from prototype to mass production is where the expertise of a zinc alloy bottle cap manufacturer truly shines. This stage involves several key steps:

- Casting and Molding: The design comes to life as molten zinc alloy is poured into molds. These molds are crafted from the prototype, ensuring each cap perfectly mirrors the approved plan.

- Detailing and Finishing: Post-casting, each bottle cap undergoes detailing. This can include engraving, adding textures, or applying colors. It’s the phase where the cap gets its unique personality.

-

- Quality Control: No cap leaves the production line without a thorough check. Manufacturers ensure each piece meets the high standards expected by clients. This includes reviews for durability, design accuracy, and overall aesthetics.

This process, while intricate, is expedited by the use of advanced manufacturing technology, allowing zinc alloy bottle cap makers to produce high-quality, consistent results at scale. It’s a blend of art and precision engineering, resulting in a product that looks good and stands the test of time.

Customization Options

Customization is where your brand can truly stand out. As a zinc alloy bottle cap manufacturer, offering a range of customization options is crucial in catering to diverse client needs. Here are some ways these caps can be personalized:

- Engraving and Embossing: Add depth to your design with engraving or embossing. This gives the caps a tactile feel that can elevate the user experience.

- Color Variations: From classic metallics to vibrant hues, color customization allows brands to align the caps with corporate colors or campaign themes.

- Texture and Finish: Options like matte, glossy, or textured finishes can significantly impact the overall look and feel of the bottle cap.

These customizations enhance the aesthetic appeal and help in brand differentiation. Whether it’s a limited edition run or a signature product line, custom zinc alloy bottle caps can be tailored to fit the unique identity of any brand.

Common FAQs Addressed

When it comes to custom zinc alloy bottle caps, clients often have several questions. Here are some of the most frequently asked ones, answered for clarity:

1. What is the Minimum Order Quantity (MOQ)?

- MOQs vary depending on the complexity and customization of the design. We work with clients to balance their needs and production feasibility.

2. How Long Does Production Take?

- Production timelines can differ based on order size and customization level. We provide estimated timelines early in the process to help with your planning.

3. Can I Get a Sample Before Full Production?

- Absolutely. Prototyping is a vital part of our process, ensuring you can review and approve a sample before we proceed with the entire order.

4. What are the Pricing Options?

- Pricing is based on design complexity, customization level, and quantity. We offer transparent quotes to ensure you understand the cost implications.

5. Are the Materials Used Sustainable?

- Sustainability is a priority. We use eco-friendly materials and processes to minimize environmental impact.

By addressing these common concerns, we aim to make ordering custom zinc alloy bottle caps as smooth and transparent as possible.

Conclusion: Your Cap, Your Story

In the world of packaging, a custom zinc alloy bottle cap is more than just a closure; it’s a statement. It reflects your brand’s identity, values, and commitment to quality. At GuanChengXin, we understand the power of a well-crafted cap. That’s why we’re dedicated to bringing your vision to life, from the initial sketch to the final product.

Whether you’re launching a new product or looking to revamp your existing packaging, our team guides you through every step. With our expertise in creating high-quality, sustainable, and bespoke bottle caps, we ensure that each hat tells your brand’s unique story.

So, why wait? Let’s create something extraordinary together. Contact us to begin your journey toward a custom bottle cap that slays!