Customize Your Own ZAMAC Cap

We help you avoid the pitfalls to deliver the quality and value your ZAMAC wine bottle cap and perfume cap need on-time and on-budget.

Material:ZAMAC 3#

Color:Water plating pearl gold coating(customizable)

Dimension:(custom)

Accessories:ZAMAC bottle cap+ABS bottle neck cover+ inside plastic part with three sets of anti-counterfeiting

| Component Name | ZAMAC liquor bottle cap/Metal wine bottle cap factory |

| Material | ZAMAC 3# |

| Color | Water plating pearl gold coating(customizable) |

| Dimension | (custom) |

| Accessories | ZAMAC bottle cap+ABS bottle neck cover+ inside plastic part with three sets of anti-counterfeiting |

| Style | We can customize production according to customer requirements, specifications, design, quantity, quality and packaging |

| Production Process | Drawing design – client confirming drawings – creating molds – First Article parts submission- FA samples Approval- die casting – polishing – electroplating – drop glue – 100% full inspection – packaging |

| Advantages | Equisite workmanship, unique design, beautiful appearance, excellent quality, competitive price , punctual delivery , creating value-added service for your products |

| Application | Can be used for all kinds of high-end wine as bottle packaging accessories |

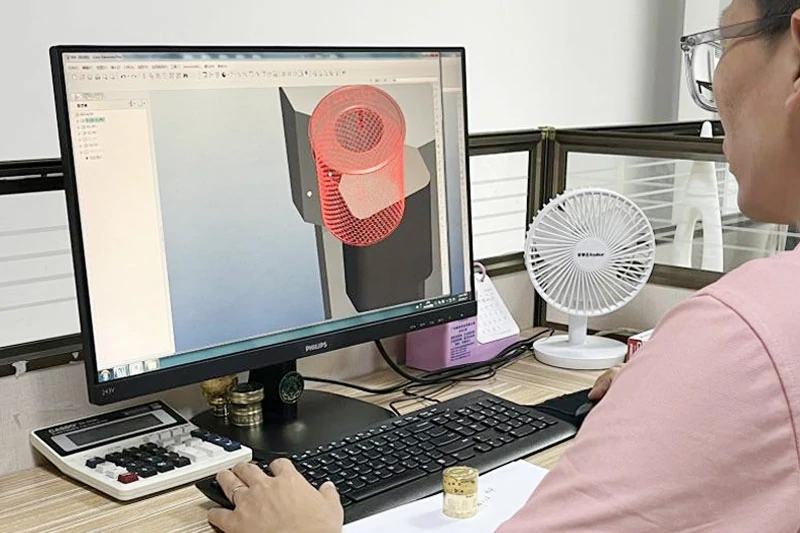

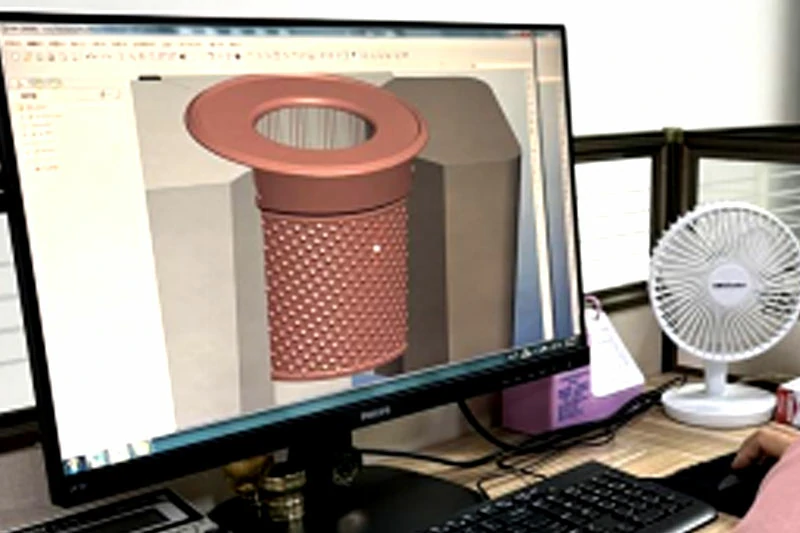

GuanChengxin, your ultimate partner, offers end-to-end services encompassing design, production, and beyond, revolutionizing bespoke packaging.

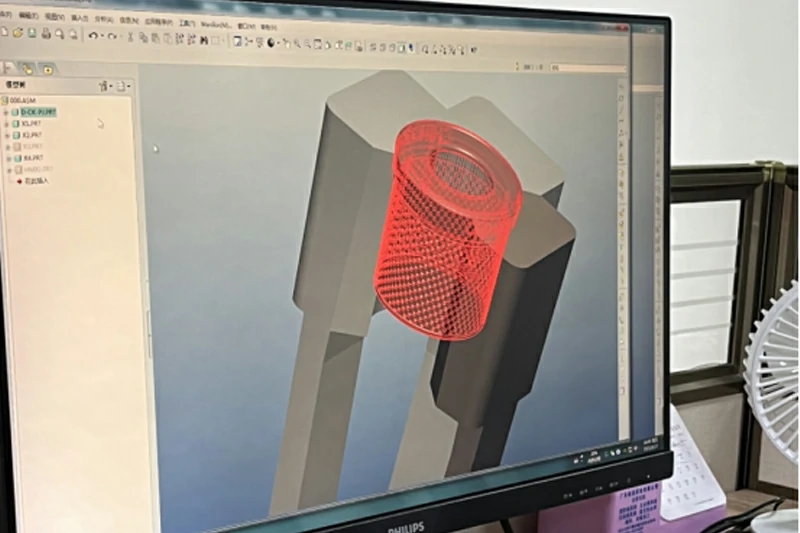

Our adept design team transforms your visions into tangible masterpieces, seamlessly bridging imagination and reality.

Adhering to rigorous global AQL benchmarks, GuanChengxin guarantees impeccable product quality, solidifying its commitment to excellence.

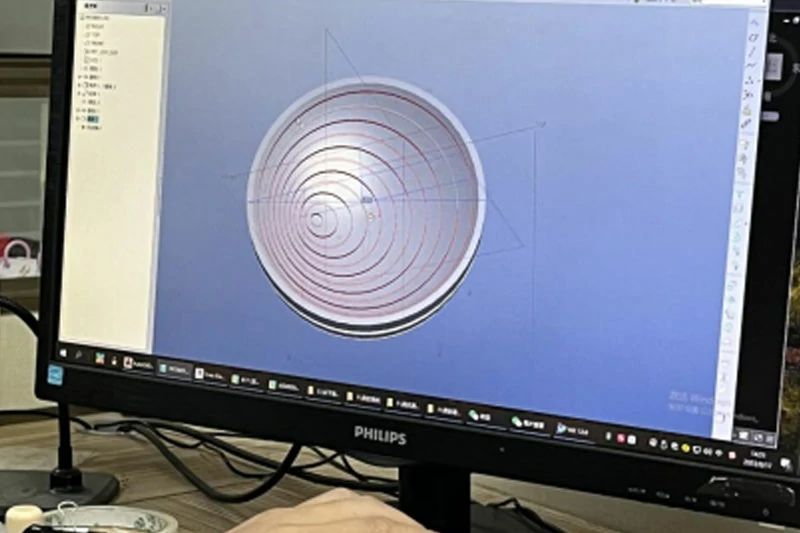

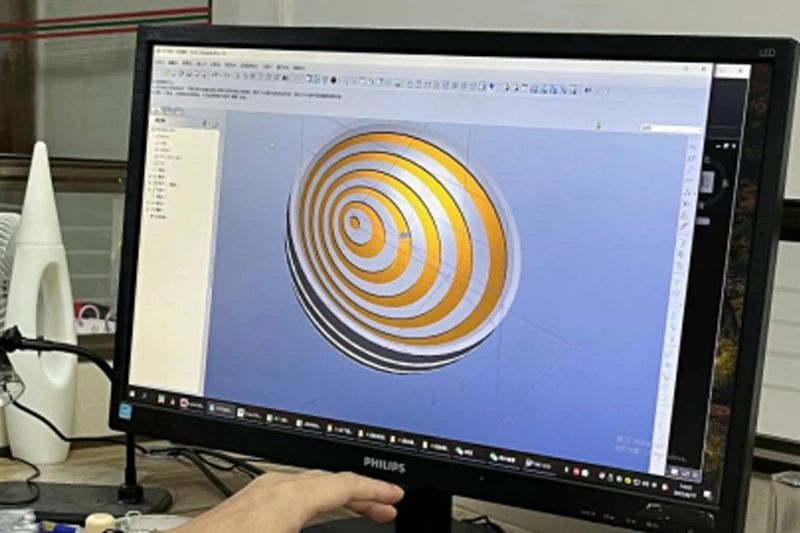

From concept to mass production, our team specializes in product development and casting innovation.

Whether it is to prototype new designs, assist you in turning the concept into reality, or design for manufacturing to optimize the overall design including lightweight, performance and cost, we are prepared to support you at the early stages of ideation and concept as well as during serial production.

We have the technical expertise to turn our product development ideas into reality, while constantly improving casting processes and methods to ensure the best parts for your business.

We can offer 3D drawing, prototype, mockup. If you have designs, please send us for checking, files in STEP, IGES, STL, OBJ, PDF, AI, JPG, PNG are available.

Creating precise molds to ensure stability of products' quality

Our die casting machines of 88T, 160T, and 200T to manufacture high quality Zamac bottle caps.

We have 60 sets hand polishing machines and 2 sets automatic polishing machines.

Certain caps, stoppers, candle caps or bottle decorations parts require CNC lathes because of structural requirements.

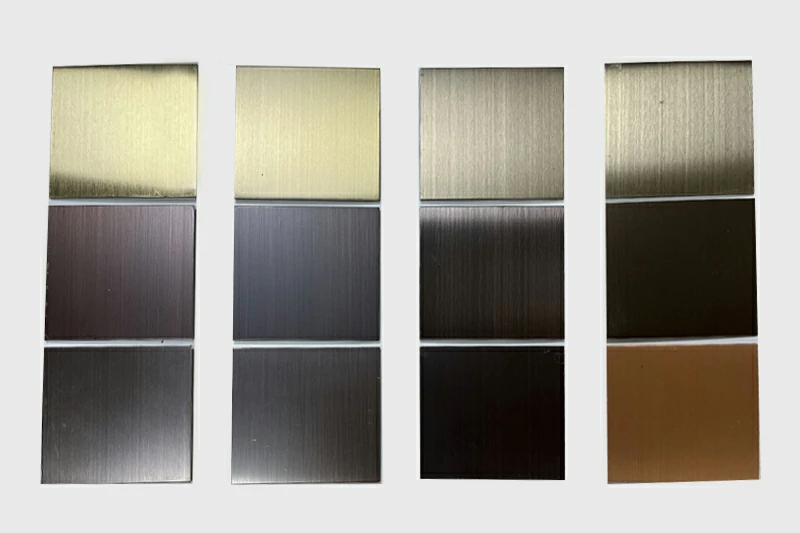

Electroplating, painting, electrophoresis and vacuum plating are available. We do 100% quality check before surface finishing.

Every product will be inspected in line with our strict quality control system.

Tailor-made packing for your products.Pack each product well on blister trays, paper trays or cover by protective films.

Making range boards to show colors and defects which is acceptable or unacceptable, for customer to check and signed. Quality will be strictly controlled within range boards.

Cartons will be stacked on pallets and wrapped in wrapping film to ensure safe arrival of products.

Premium Quality Products Have Been Done With High Standard Surface Treatment Which Can Pass All Tests Required In The Industry

Guanchengxin Carry Out Incoming Inspection, Ipqc, Dpi And 100% Quality Check Before Packing.

This is the first step of all the communications. Customers can send us designs and drawings directly or we can draw 2D or 3D for customers.

Based on the requirements and drawings, we proceed the tooling and molding for the product.

We have different kinds of techniques and ways for die casting.

Removing the gates/flash or burrs is the basic step for the following polishing.

It will be intensive surface treatment process, and it will help the next electroplating step more favorably.

It can make the caps shining and luxury and enhance the corrosion resistance ability.

We provide 100% quality check service to make our customers can get 100% exquisite high quality bottle cap.

We provide different options for keeping the perfume caps safely during long time shipment, including custom EVA, plastic tray, etc,. Particularly the custom EVA can fit the perfume cap very well.

Usually it will be T/T in advance , we also can accept net 30 days for the long-term cooperation customer. Please check with our sales with details.

Normally, the customized samples lead time is 15 days, the lead time for mass production is 25-30 days. It depends on the order quantity and the season you place the order.

Yes,we have a professional team can make design drawing and 3D display to you. Also we can support you 3D samples.

We can accept FOB,CIF etc. You can choose the one which is the most convenient or cost effective for you.

No, you do not need to pay for the mold again, it will be used for a long time.

We are a reputable supplier of metal perfume bottle caps, and we specialize in customizing perfume bottle caps to meet specific preferences and requirements.

We help you avoid the pitfalls to deliver the quality and value your ZAMAC wine bottle cap and perfume cap need on-time and on-budget.

Copyright © 2023 GUANCHEGNXIN- All Rights Reserved