Why Choose us

Customization Process

Our production capacity, innovation ability and management level have reached the advanced level of the same industry in China, and becomes one of the largest manufacturer and supplier in the domestic zinc alloy die casting industry.

01

Design ablity

Our experienced design teams can assist in prototyping and bringing your concepts to life, offering unique and innovative designs. We also focus on optimizing overall design, including aspects like lightweighting, cost-efficiency, and performance. We are fully prepared to provide you with our best support as needed.

We require clear pictures, samples, 2D drawings (in pdf or CAD files), and 3D drawings (in STP, IGES, ASM, PART) for accurate and timely quotations within 2 working days.

02

Mold Creating

We have an in-house mold-making room with all essential facilities, allowing us to efficiently control mold quality and ensure a short lead time of 25 working days. Our experienced team excels in high-quality service and swift tooling construction.

03

Die casting process

We are very experienced in ZAMAC die casting with all kinds of tons of automatic die-casting machines in house and master the expertise to ensure the stable quality. All our manufacturing processes are done in our factory which allows us to cut down on delivery time.

04

Basic appearance treatment

Removing the gates and flash, deburring etc. To decrease the labor cost and enhance the production efficiency, we use several advanced ultrasonic wave equipment to remove the gates instead of pure labor as the video shown.

05

CNC lathe Machining

We can do CNC lathe machining to achieve the dimensional precision and also can provide drilling or tapping and other processes in house to fulfill any needs.

06

Polishing

We own two advanced automatic polishing production lines. And meanwhile 60 labor hand polishing machines work together. All of our workers are well trained and quite experienced with operation skills. And all the technician are very professional in polishing process. This plays a very important role in expanding production capacity.

07

Surface finishing

Various surface treatment for options and electroplating is used commonly. ZAMAC can be finished with different metallic colors such as silver, gold, rose gold, matte shiny etc and other surface treatment like painting, powder coating ,sand-blasting etc are available. We have qualified engineering in this field to provide you the best suggestion and solutions.

08

Quality Assurance

Since most of our customers are luxury brands, the quality is always the essential key we care about. Our QC stays at every production process to check one by one, 100% inspection in every step, and 5% random checking again before shipment.

09

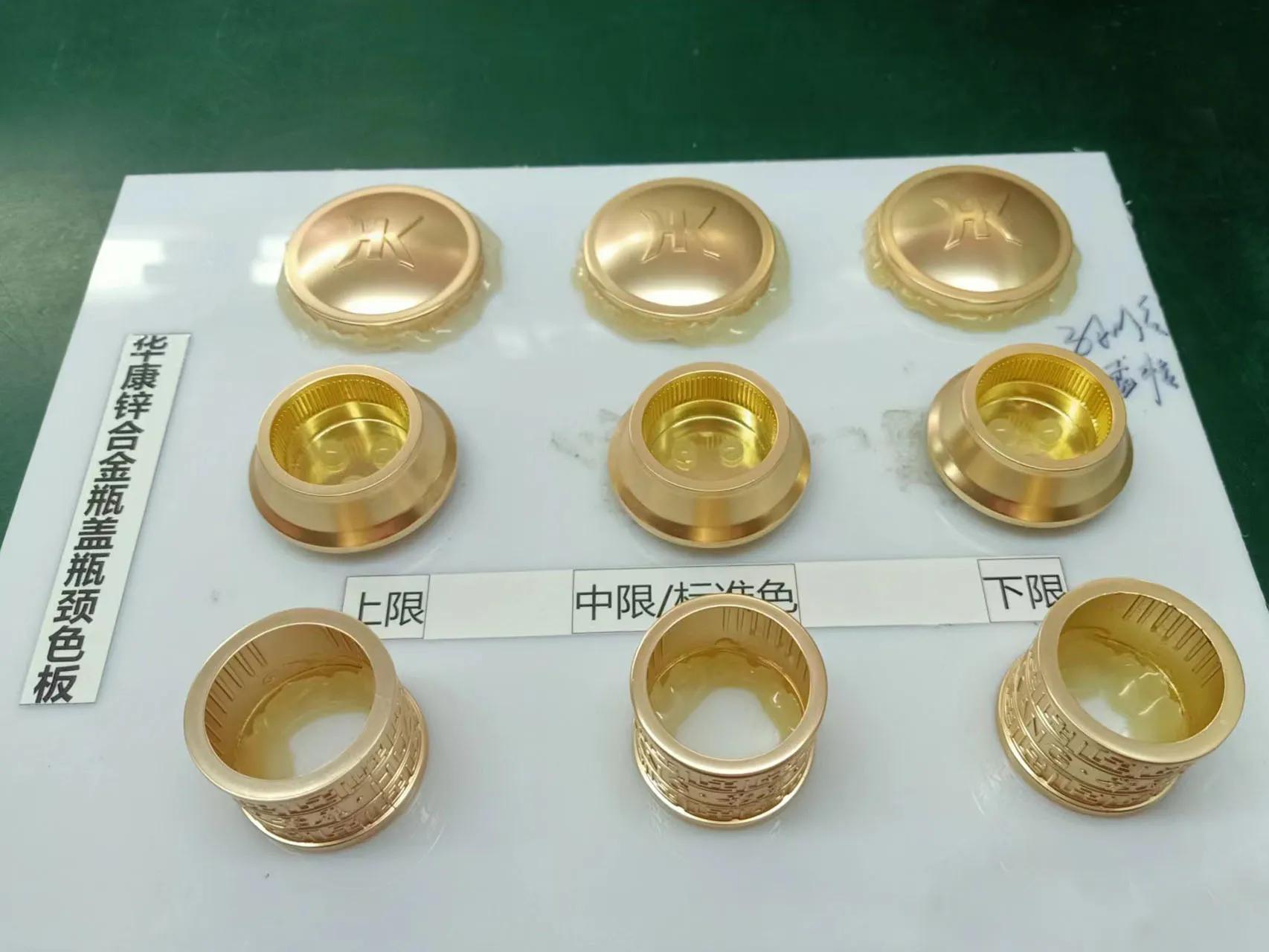

Range Boards Check

Making range boards to show colors and defects which is acceptable or unacceptable, for customer to check and signed. Quality will be strictly controlled within range boards.

10

Assembly and packing

We have our own two assembly production lines in house . For safe packing we use blister trays, big waterproof bags and qualified cartons for protecting each Zamac cap during transportation.

Our Bottle Caps

In order to demonstrate the brand high-end level, many brands are trying everything to find ways to make themselves more unique in terms of products and packaging. The use of metal Zamac (zinc alloy) die-casing wine bottle caps and perfume bottle caps can make the products more textured and make the brand image more luxury. we have been supporting countless of brand holders to build up their brand image with high quality and well made zinc alloy caps.

For Brand Owners

Taking ideas to tangible elegance, we specialize in crafting perfume caps. We guide you through refining concepts and actualizing your brand's signature packaging.

For Manufacturers & Suppliers

With an advanced in-house facility, we offer premium perfume cap options. As a manufacturer or supplier, trust our streamlined processes for top-tier market offerings.

For Wholesalers

As a premier perfume cap manufacturer, we provide top-quality products at competitive prices. Collaborate with us to extend exceptional value to your customers.

Are You Ready To Custom Your Own Zamac Bottle Cap Or Zamac Perfume Cap?

Our experienced designer team will communicate with you in the first step, and the engineer colleagues will combine the feasibility of production to ensure your design can come true successfully.Just feel free to contact us now!

FAQ

Usually it will be T/T in advance , we also can accept net 30 days for the long-term cooperation customer. Please check with our sales with details.

Normally, the customized samples lead time is 15 days, the lead time for mass production is 25-30 days. It depends on the order quantity and the season you place the order.

Yes,we have a professional team can make design drawing and 3D display to you. Also we can support you 3D samples.

We can accept FOB,CIF etc. You can choose the one which is the most convenient or cost effective for you.

No, you do not need to pay for the mold again, it will be used for a long time.

Get a Free Quote

We are a reputable supplier of metal perfume bottle caps, and we specialize in customizing perfume bottle caps to meet specific preferences and requirements.