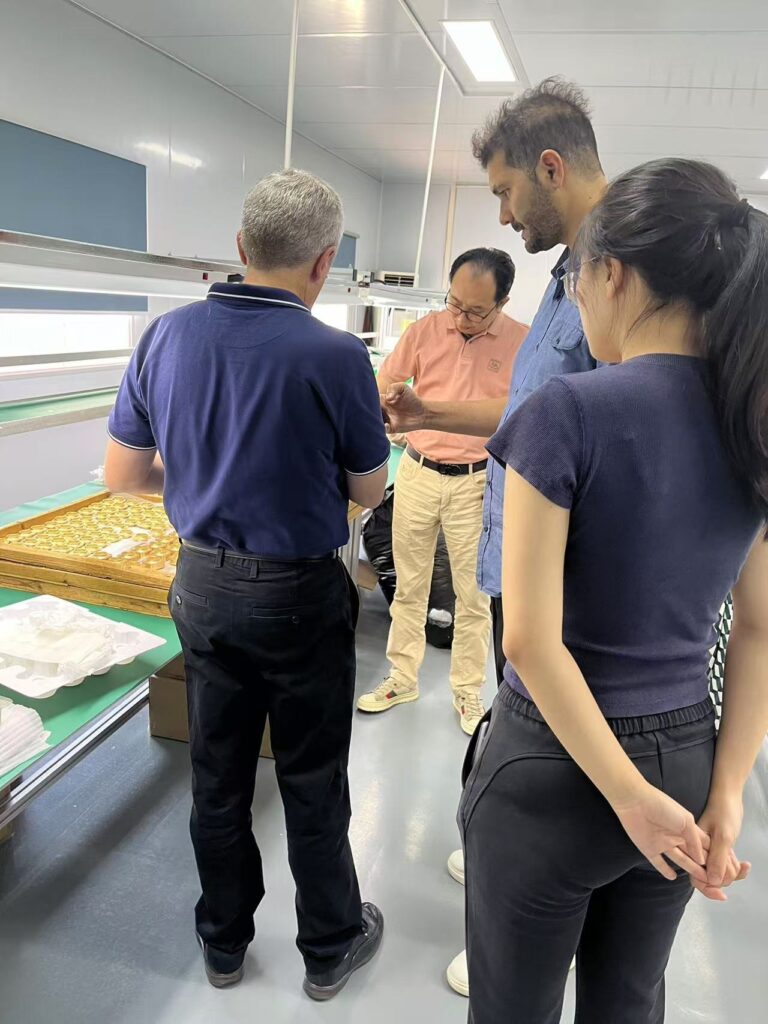

On November 8, 2024, a delegation from Argentina visited our company for an in-depth tour and evaluation of our products, including Zamac wine bottle caps, perfume bottle caps, and other zinc alloy die-cast components. During the visit, the client was highly impressed with our product quality and manufacturing capabilities, expressing their full satisfaction.

Our company is a leading manufacturer specializing in Zamac zinc alloy die-cast components, and we have built a solid reputation for producing high-quality products such as wine bottle caps and perfume bottle caps. These products, known for their exquisite craftsmanship and durability, are in high demand and are exported worldwide. This visit reaffirmed our position as one of the largest manufacturers and suppliers in the zinc alloy die-casting industry.

The client was given a comprehensive tour of our production facilities, where they were introduced to our advanced manufacturing processes and equipment. Our company boasts a highly skilled technical management team with over 20 years of experience in the industry. We have more than 80 pieces of state-of-the-art equipment, including zinc alloy die-casting machines, CNC lathes, automatic polishing machines, spark machines, punch presses, and milling machines. With an annual production capacity of over 8 million units, our production, innovation, and management capabilities are at the forefront of the domestic industry.

After observing the entire production process, the client expressed admiration for the exceptional quality of our products. They particularly appreciated the fine details, durability, and aesthetic design of our Zamac bottle caps, noting that these features set our products apart from other suppliers. This feedback reinforced their decision to pursue a long-term partnership with us.

In addition to our product quality, the client was also impressed with our end-to-end service, which covers everything from design to production. Our team works closely with clients to create unique packaging solutions that reflect their brand’s identity. This is particularly important for our perfume bottle cap clients, as we help them transform creative ideas into elegant, signature packaging that stands out in the market.

Overall, the visit was a resounding success, and the Argentine client left with a strong sense of confidence in our capabilities. We look forward to building lasting partnerships with more global brands, manufacturers, and suppliers, helping them enhance their brand image with our premium Zamac products.

Our company remains committed to delivering high-quality zinc alloy die-cast products and will continue to innovate and improve our manufacturing processes to meet the demands of the global market.